The Future of Electronics: 3D

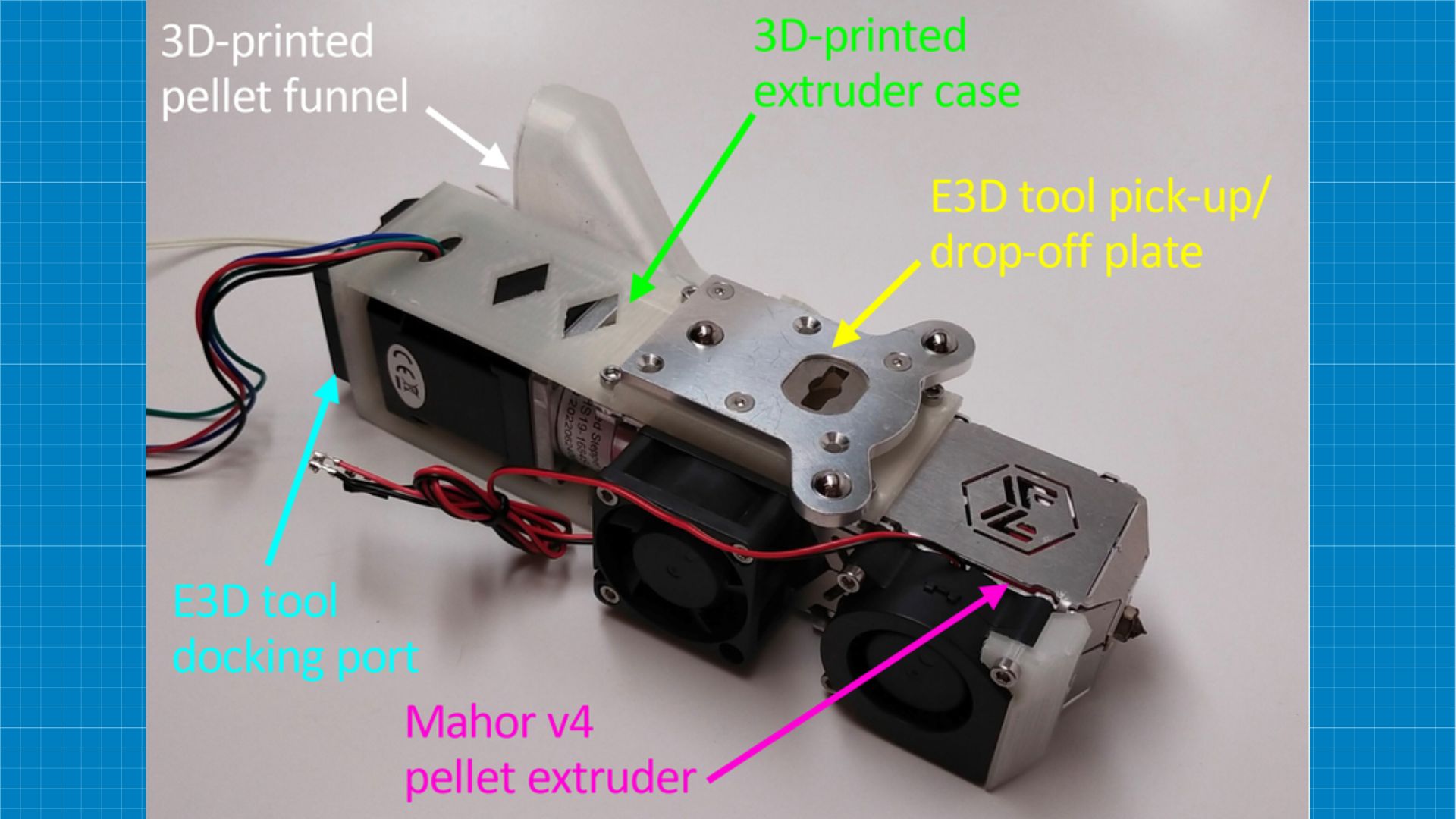

By subscribing,巴西彩票种类 you agree to our Terms of Use and Policies You may unsubscribe at any time. In a remarkable leap forward, engineers at the Massachusetts Institute of Technology (MIT) have achieved a significant breakthrough in electronics manufacturing: the creation of fully 3D-printed, three-dimensional solenoids. These electromagnets, which serve as crucial components in a wide array of electronic devices, promise to revolutionize industries both on Earth and in space. The implications of this advancement are profound. By enabling the fabrication of intricate electronic components such as solenoids using 3D printers, MIT is paving the way for a more inclusive and accessible approach to technology. Speaking to MIT News, Luis Fernando Velásquez-García, principal research scientist at MIT, emphasized global need, saying, “There is no reason to make capable hardware in only a few centers of manufacturing when the need is global.” Velásquez-García also highlighted their vision to empower people in distant places to make hardware themselves, instead of relying on shipping. This democratization of technology will potentially reshape industries and improve lives, particularly in underserved communities and remote areas with limited access to traditional manufacturing facilities. While 3D-printed electronics are not entirely novel, MIT researchers faced formidable challenges in bringing their vision to fruition. Traditional solenoid manufacturing processes involve intricate assembly procedures and specialized cleanroom environments. The MIT team overcame these obstacles by leveraging additive manufacturing, which enabled them to produce solenoids of virtually any size and shape with unprecedented efficiency and precision. Furthermore, they modified the printer to extrude pellets instead of filament in order to use soft magnetic nylon, a material offering superior performance but cannot be produced as a filament. Central to their success was customizing a commercial extrusion 3D printer to accommodate multiple materials seamlessly, which allowed for the precise layering of dielectric, conductive, and soft magnetic materials essential for solenoid fabrication. Despite initial skepticism surrounding extrusion printers, their simplicity proved an asset, enabling multimaterial, monolithic printing—a pivotal aspect of the project’s success. The 3D-printed solenoids exhibited exceptional performance; they cannot surpass the capabilities of their conventionally manufactured counterparts. With a magnetic field strength three times greater than traditional devices, these solenoids unlock many applications, ranging from miniature sensors to advanced robotics. Moreover, their compact size and enhanced efficiency make them versatile solutions for various electronic devices. The team modified a 3D printer to print compact, magnetic-cored solenoids in one step. MIT News Looking ahead, the MIT team is committed to further refining their process and exploring alternative materials and optimization techniques. By fine-tuning temperature control mechanisms and deposition methods, they aim to push the boundaries of 3D-printed electronics even further, unlocking more possibilities and potential applications. Supported by funding from the Empiriko Corporation, this groundbreaking research underscores the transformative power of collaboration and innovation in advancing technology. As the field of 3D-printed electronics continues to evolve, MIT remains at the vanguard of progress, driving innovation and shaping the future of manufacturing. With each breakthrough comes the opportunity for further exploration and discovery. As MIT engineers continue to push the boundaries of 3D-printed electronics, the world eagerly anticipates the unfolding of new possibilities. From healthcare advancements to space exploration, the impact of this transformative technology knows no bounds. The team’s research was published in the journal Virtual and Physical Prototyping.Democratizing cutting-edge technology

Charting a course for future innovation

- 最近发表

-

- In India, a legislative reform is needed to push corporate social responsibility

- We Are Ready For Nuclear War, French President Warns Putin

- Boy Afraid

- Charlie Louvin, 1927

- One of the Country’s Largest Egg Producers Accused of Pandemic Price Gouging

- Bird Flu Is Back in the US

- Scientists Disagree Over Earth Heating Due To Climate Change

- Researchers develop aerogel

- 2.1 Million Animals in Mongolia Have Died of Extreme Cold

- Apple to Integrate Google's Gemini AI Service Into iPhone

- 随机阅读

-

- French Police Seize 72 Guns From Film Star's Home

- Low, Dishonest Days

- First, tweet through Neuralink, now Musk's Blindsight aims for sight

- Scientists Disagree Over Earth Heating Due To Climate Change

- Family Punditry

- EPA Launches Investigation Into North Carolina Hog Operations

- Bird Flu Is Back in the US

- Scientists Disagree Over Earth Heating Due To Climate Change

- Imaginary Current Events

- Facing disasters: lessons from a Bangladeshi island

- Trump’s new Afghanistan strategy gets one thing right but questions remain

- Waking The Dead

- Seaweed May Be the Answer to the Burping Cow Problem

- China Warns US of Consequences For Banning TikTok

- Biden Administration Returns to Trump

- Fast Food Giant McDonald's Suffers Global IT Failure

- Joe Biden Wins Crucial Michigan Primary Despite Protest Vote

- Florida Forecasted to Have Smallest Orange Crop Since 1945

- Steve Jobs, Dead at 56

- Punk Icon and Spiritual Seeker Set Free From Outer Shell

- 搜索

-

- 友情链接

-